Cnc Turned Components Wholesale - Jiarong

Product details of the cnc turned components

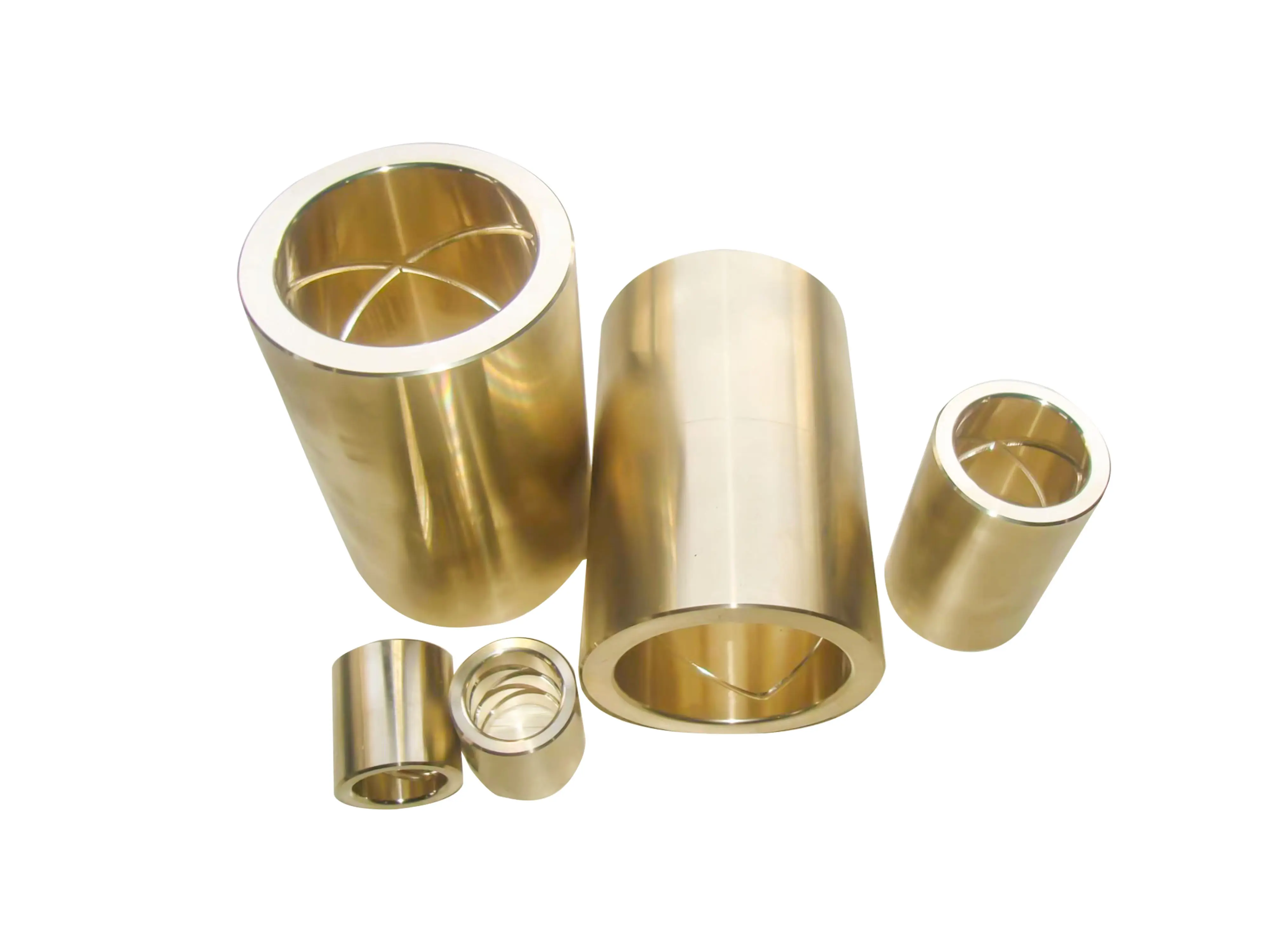

Product Description

Jiarong cnc turned components is produced at a quick rate due to increased the efficiency of production. The product is in the best quality at competitive, affordable prices. After years of exploration and practice, Shenzhen Jiarong Precision Industry Co., Ltd has established perfect quality control system.

Product Information

◆ Application: Medical accessory, Fastener, Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory

◆ Standard: GB, EN, API650, China GB Code, JIS Code, TEMA, ASME

◆ Surface Treatment: Anodizing

◆ Machining Method: CNC Lathing

◆ Material: Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron

◆ Samples: Available

◆ Customization: Available

◆ Shipping Cost: Negotiate with supplier about shipping cost and estimated delivery time.

◆ Return&refunds: You can apply for a refund up to 30 days after receipt of the products.

Product parameters

|

Service |

CNC Turning, CNC Milling, Laser Cutting, Wire Cutting, Stamping,Electric Discharge Machining (EDM), Plastic Molding. |

|

Materials |

1). Aluminum: AL 6061-T6, 6063, 7075-T, etc2). Stainless steel: 303,304,316L, 17-4(SUS630) etc3). Steel: 45#, Q235, Q345B4). Titanium: TA1,TA2/GR2,TA4/GR55). Brass: C36000 (HPb62)6). Copper, bronze, POM, Acrylic, PC, etc. |

|

Surface Treatment |

Sandblasting, Anodize, Zinc/Nickle Plating, Polish |

|

Processing Technology |

CNC machining parts, turning/milling process |

|

MOQ |

1pcs |

|

Lead Time |

Sample: 3-5 days.Mass Production: within 10-25 days after receiving the deposit. |

|

Package |

1)pp bags + carton or wooden case2) according to customers' requirements3)negotiable |

|

Payment Terms |

Trade Assurance, T/T/ West Union |

Product Display

FAQ

Company Feature

• The geographical advantages and open traffic are conducive to the circulation and transportation of CNC Machining Parts , Mold , CNC Milling Parts , CNC Lathe and Mill Parts , CNC Turning Parts.

• Jiarong has experienced the laborious development of years unconsciously. During these years, we have constantly pursued our dreams and have achieved self-breakthrough.

• Jiarong has a professional customer service team to provide quality and considerate services for customers.

• Our company has vigorously explored the domestic and overseas markets through various means. Currently, the products are successfully entered into some countries and regions in Europe, America and Australia.

• Jiarong has a first-class product development team and a professional quality management team, which provides a solid guarantee for improving products.

If you want further information about the detail and price about the custom service for CNC Machining Parts , Mold , CNC Milling Parts , CNC Lathe and Mill Parts , CNC Turning Parts, please leave your contact information. Jiarong would reply you soon and your patience would be much appreciated.

Contact: Jason Guo

Phone Number: +86 13824306389

Email:jack926@jiarongsz.com

Add: 3rd Floor, Building C, Shangnan Jinyuda Industrial Park, Shangliao Community, Xinqiao Subdistrict, Bao'an District, Shenzhen, Guangdong, China

Monday - Friday: 8:00am - 6:00pm

Saturday: 9:00am - 6:00pm

Copyright © 2025 Shenzhen Jiarong Precision Industry Co., Ltd. - www.jrcncmachining.com | Sitemap | Privacy Policy